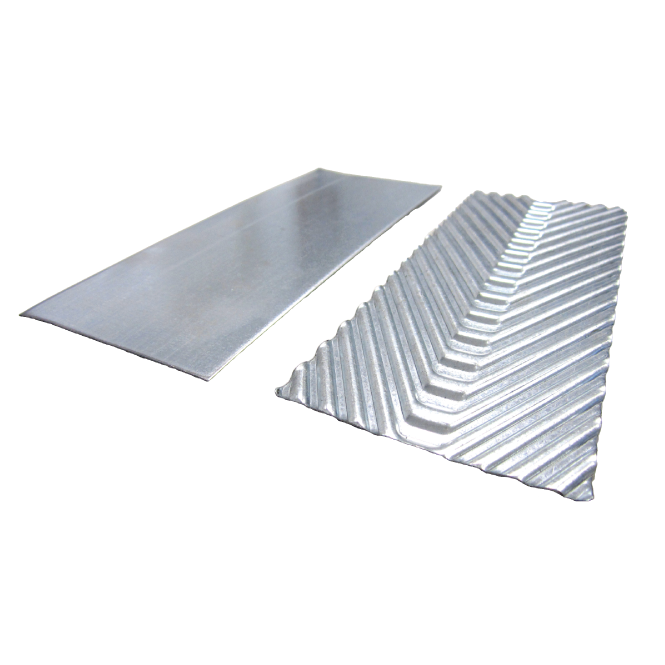

The Sendzimir method consists of hot dip galvanizing before processing. The process consists of a treatment that involves the passage of the sheet metal in a bath of molten zinc at 650°. Before passing through the zinc, the sheet is subjected to a degreasing treatment to remove surface impurities and then pickled in hydrochloric acid to eliminate iron oxides. The total zinc thickness on both sides ranges from Z 200 to Z 275 g/m2 (UNI EN 10346).

Galvanic coatings offer triple protection to the steel underneath:

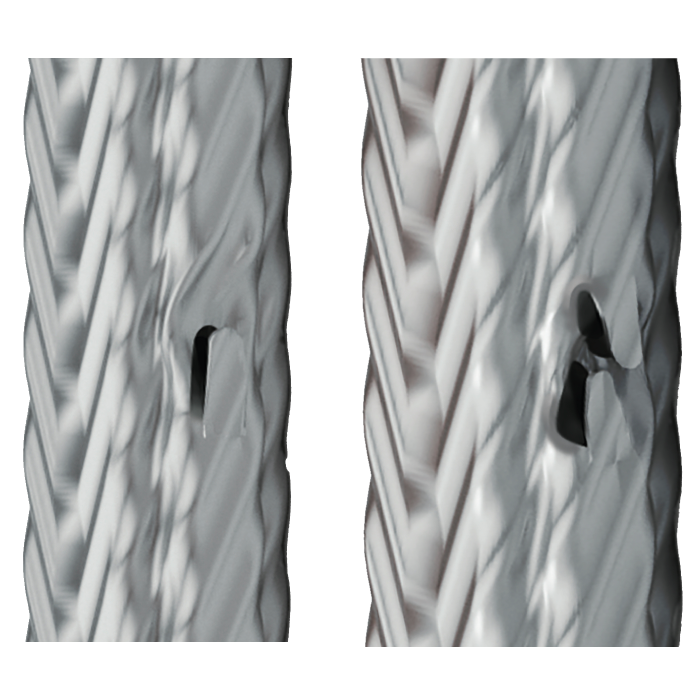

- Protection by barrier effect: the coating insulates the steel from the external corrosive environment.

- Cathodic or sacrificial protection: Zinc forms the anodic part in the corrosion stack and corrodes slowly protecting the steel. As long as there is zinc on the surface, the steel will not suffer any corrosion.

- Sealing of uncovered areas: The zinc corrosion products, which are insoluble, compact and adherent, seal the areas of the steel which, for whatever reason (shocks, scratches, etc.), accidentally has been exposed to the external environment. This procedure provides additional protection for the substrate.